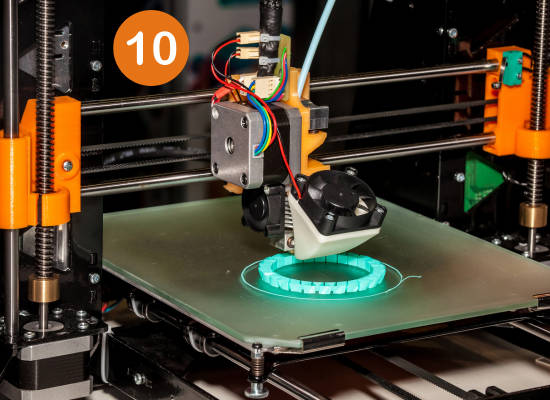

10-Step Guide to Launching 3D Printing Across Your Fleet

Welcome to the game-changing world of 3D printing on commercial ships! It’s like having a futuristic mini-factory on board that can whip up everything from door handles to complex machinery parts. Here is your quick 10 step guide to 3d printing success!

* Please send feedback/suggestions to editor @ shipuniverse.com

#1 Assessment and Planning: Charting Your Course

Where Are We Going? Start by mapping out your 3D printing adventure. Think about the parts that tend to give up the ghost more often than you’d like and how a printer could become your secret weapon. This is your chance to dream about the endless possibilities while keeping your feet firmly on deck.

Drawing the Map Consider this step your very own blueprint creation. What do you need? How often? How can 3D printing ease the burden of maintenance? Answering these questions helps you sketch a clear path forward.

#2 Selecting the Right 3D Printer: Choosing Your Vessel

Size and Type Matter Just like picking a ship for a journey, choosing a printer means finding the right fit. You’ll need to think about how much room you have and the types of items you want to create. Whether it’s an FDM that prints with filaments or an SLA for precision, your choice will pave the way for what’s possible on board.

Features and Flexibility Dive into the specifics: How detailed can the prints be? What size objects can it handle? Imagine this as fitting your ship with the best gear for the voyage ahead, ensuring it can handle whatever the sea throws at it.

#3 Material Selection for Printing: Stocking Your Supplies

What’s in Your Cargo Hold? Choosing materials is akin to loading your ship with the right kind of cargo. Each type of filament or resin has its own strengths, whether it’s durability, flexibility, or fine detail.

Balancing Cost and Quality Here’s where you weigh your options between premium materials for critical parts and more cost-effective solutions for everyday items. It’s all about finding the right mix that keeps your ship sailing smoothly without breaking the bank.

#4 Designing and Modeling for Maritime Needs: Crafting Your Blueprint

Tailoring to Your Ship’s Needs Every ship has its quirks and specific needs. Here, you’ll dive into designing and modeling parts that are just the right fit for those unique challenges. Think of it as custom-tailoring outfits; only these are for your ship’s many components.

Using the Right Tools Getting your designs from ideas to printable files means using CAD (Computer-Aided Design) software. Whether you’re sketching a new part from scratch or tweaking an existing design, the right software is like your digital drafting table—essential for bringing your visions to life.

#5 Training Crew on 3D Printing Operations: Building Your Team

Learning the Ropes Just like any ship operation, knowing how to run your 3D printer is key. This step is all about getting your crew up to speed with the basics of 3D printing—how to set it up, start a print job, and troubleshoot common issues. Think of it as essential training for your seafaring adventurers.

Hands-On Practice There’s no substitute for hands-on experience. After the basics, give your crew the chance to get their hands dirty (figuratively, of course). Let them try designing simple items, printing them, and even doing some post-processing work. It’s all in the name of making them confident and competent 3D printing sailors.

#6 Establishing Safety Protocols: Navigating With Care

Safety First 3D printers, especially when used in the close quarters of a ship, come with their own set of safety considerations. From managing high temperatures to handling materials, setting up clear safety protocols is a must. This is about ensuring everyone knows how to avoid getting burned, literally and figuratively.

Regular Maintenance and Checks Just like any piece of crucial ship equipment, your 3D printer needs regular care. Establish routines for checking the printer’s condition, performing maintenance, and ensuring materials are stored safely. It’s like keeping your ship sea-worthy; regular checks keep everything running smoothly and safely.

#7 Integrating 3D Printing into Maintenance Procedures: Streamlining Repairs

Seamless Integration Think of your 3D printer as the new crew member who’s always on call. The goal is to weave 3D printing into your ship’s maintenance fabric, making it a go-to solution for repairs and parts replacements. This means identifying which maintenance tasks can benefit most from on-demand printing and adjusting your procedures accordingly.

Custom Repair Kits Imagine having a digital toolbox at your fingertips. By creating a library of 3D designs for commonly needed parts, you ensure quick access and production, turning what used to be a wait into a matter of hours.

#8 Testing and Quality Assurance: Ensuring Seaworthiness

Putting Parts to the Test Just like any new equipment onboard, parts made with your 3D printer need to pass the muster. Establishing a testing protocol for printed items ensures they meet the strength, durability, and safety standards required for the high seas.

Quality Control Quality assurance isn’t a one-and-done deal; it’s an ongoing commitment. Regularly review and update your testing procedures to keep up with advancements in printing technology and materials, ensuring every part remains up to par.

#9 Inventory Management and Digital Cataloguing: Navigating Your Digital Warehouse

Digital Stock Takes Gone are the days of physical storerooms filled to the brim. With 3D printing, your inventory goes digital. Implementing a system to manage and catalog your digital designs helps you keep track of what you have, what you need, and what you can produce on demand.

Efficient Resource Management This step is all about balancing your material supplies with your printing needs. By monitoring usage and anticipating needs, you can maintain an efficient inventory that minimizes waste and ensures you have the materials on hand when needed.

#10 Continuous Learning and Upgrading: Charting a Course for Innovation

Staying Ahead of the Wave The world of 3D printing evolves rapidly. Keeping your skills, knowledge, and equipment up to date is crucial for maximizing the benefits of on-board 3D printing. Encourage a culture of continuous learning among your crew, making room for experimentation and innovation.

Future-Proofing Your Operations As you gain experience and confidence, look for opportunities to upgrade your equipment and expand your printing capabilities. Whether it’s investing in faster, more precise printers, exploring new materials, or integrating advanced design software, staying ahead of the curve ensures your ship and crew are always ready for the future.

Discover your Ideal 3d Printing Solution Today

Do you have a Maritime Product or Service that may be of interest to Shipowners? Tell us about it here!

Do you have feedback or insights? Please reach out to editor @ shipuniverse.com