20 Essential Tips for Launching 3D Printing Onboard Ships

In the ever-evolving maritime industry, 3D printing is emerging as a revolutionary tool, transforming how ships manage maintenance and repairs while at sea. This technology empowers vessels to create necessary parts on-demand, significantly reducing downtime and dependency on distant suppliers. As the adoption of onboard 3D printing continues to grow, understanding how to effectively implement this technology is becoming crucial for ship owners and operators. Here are 20 expert strategies that provide a comprehensive roadmap to successfully start 3D printing parts onboard, ensuring your crew is equipped and ready to handle this innovative capability.

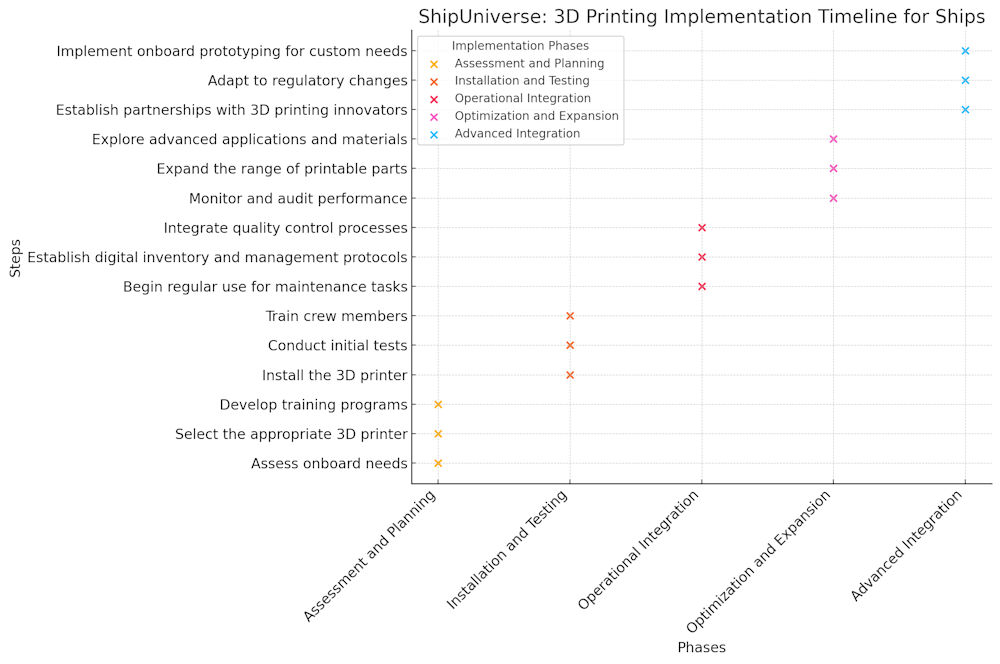

1. Assess Onboard Needs and Opportunities

- Objective: Identify frequently needed or critical spare parts.

- Action: Conduct an audit of maintenance records to pinpoint which parts are most commonly replaced or cause downtime due to delays in sourcing.

- Benefit: Pinpointing specific areas where 3D printing can immediately impact efficiency and cost savings.

2. Select the Right 3D Printer

- Objective: Choose a printer capable of handling maritime-specific materials and environmental conditions.

- Action: Evaluate printers based on material compatibility (plastics, metals), stability in varying sea conditions, output resolution, and ease of use.

- Benefit: Ensuring the selected printer can reliably produce high-quality parts that meet the rigorous demands of maritime operations.

3. Train Crew Members

- Objective: Develop crew expertise in 3D printing operations and design modifications.

- Action: Implement a training program that includes operational techniques, safety procedures, and software handling for designing and modifying parts.

- Benefit: Empowers crew members to manage the entire printing process independently, from design adjustments to final production.

4. Establish a Digital Inventory

- Objective: Create a readily accessible digital library of designs for necessary parts.

- Action: Develop a comprehensive digital catalog of CAD files and ensure they are optimized for onboard printing. Include common and custom parts designs.

- Benefit: Reduces response time in emergencies by providing instant access to part designs, facilitating immediate production.

5. Integrate Quality Control Processes

- Objective: Ensure that printed parts meet safety and durability standards.

- Action: Set up protocols for testing and verifying the quality of printed parts, possibly integrating sensors in the printer for real-time quality checks.

- Benefit: Maintains the integrity of ship operations by ensuring all manufactured parts are reliable and fit for use.

6. Collaborate with Regulatory Bodies

- Objective: Ensure compliance with maritime safety and equipment regulations.

- Action: Engage with maritime regulatory authorities to understand and align with all regulations regarding the use of printed parts in vessels.

- Benefit: Avoids legal and safety issues by ensuring that the use of 3D printed parts is fully compliant with international maritime regulations.

7. Secure Reliable Material Supply Chains

- Objective: Maintain a steady supply of printing materials that meet maritime standards.

- Action: Identify and partner with suppliers who can provide high-quality, sea-grade materials for 3D printing.

- Benefit: Ensures the availability of appropriate materials that can withstand marine environments, preventing delays in printing operations.

8. Implement Onboard Prototyping

- Objective: Leverage 3D printing for rapid prototyping aboard the ship.

- Action: Use 3D printing to experiment with and test new parts or modifications before final production.

- Benefit: Enables in-situ testing and refining of designs, improving the efficiency and effectiveness of parts before they are put to use.

9. Develop an Emergency Printing Protocol

- Objective: Establish clear procedures for emergency print jobs.

- Action: Define scenarios and protocols for prioritizing and executing prints during critical situations, ensuring all crew are familiar with the process.

- Benefit: Enhances the ship’s resilience by allowing for rapid response to part failures that could impact safety and operations.

10. Optimize Printing Environment Onboard

- Objective: Create optimal conditions for the 3D printer to function reliably at sea.

- Action: Modify and prepare a dedicated space on the ship that controls temperature, humidity, and vibration, ensuring stable printing conditions.

- Benefit: Prevents printer malfunctions and poor-quality prints caused by the harsh marine environment, leading to more reliable part production.

11. Set Up a Remote Support System

- Objective: Ensure ongoing technical support for the 3D printing process.

- Action: Establish a system for remote troubleshooting and support with the printer manufacturer or a 3D printing expert, allowing crew members to receive assistance in real-time.

- Benefit: Minimizes downtime and enhances the reliability of the 3D printing setup by providing expert assistance when needed.

12. Regularly Update and Back Up Printer Software

- Objective: Keep the 3D printing system up-to-date and secure.

- Action: Implement regular software updates and maintain backups of all critical software systems associated with the 3D printer.

- Benefit: Ensures the printing system remains efficient and secure against potential cyber threats, while also incorporating the latest improvements and features.

13. Implement Onboard Material Handling Safety Protocols

- Objective: Ensure safe handling and storage of 3D printing materials.

- Action: Develop comprehensive safety protocols for storing and handling various printing materials, especially those that may be hazardous or sensitive to environmental conditions.

- Benefit: Reduces the risk of accidents and ensures the longevity and quality of printing materials, promoting a safe working environment.

14. Conduct Regular Performance Audits

- Objective: Continuously assess the performance and output of the 3D printer.

- Action: Schedule regular audits to evaluate the efficiency, accuracy, and reliability of the 3D printing operations. Use the findings to optimize processes and update training as needed.

- Benefit: Maintains high standards of print quality and operational efficiency, ensuring the technology meets the needs of the ship effectively.

15. Establish Partnerships with 3D Printing Innovators

- Objective: Stay at the forefront of 3D printing technology and its applications in maritime settings.

- Action: Form strategic partnerships with technology providers and innovation leaders in the 3D printing industry. Participate in collaborative projects to develop new solutions tailored to maritime challenges.

- Benefit: Ensures access to the latest advancements and custom solutions in 3D printing, keeping the ship’s capabilities ahead of the curve.

16. Monitor and Adapt to Regulatory Changes

- Objective: Ensure compliance with all current and future regulations affecting 3D printing at sea.

- Action: Keep abreast of international maritime regulations and standards that may impact 3D printing operations. Adjust practices accordingly to ensure continuous compliance.

- Benefit: Protects the ship and its management from legal complications and ensures that operations align with global standards, enhancing the credibility and reliability of the printing setup.

17. Promote Innovation and Continuous Learning

- Objective: Foster a culture of innovation and continuous improvement around 3D printing technology.

- Action: Encourage crew members to propose improvements and innovations in the use of 3D printing, offering incentives for ideas that enhance efficiency or solve onboard challenges.

- Benefit: Engaging the crew in this way not only improves the operations but also boosts morale and fosters a proactive approach to problem-solving and technology usage.

18. Integrate with Inventory Management Systems

- Objective: Streamline the integration of 3D printed parts into the ship’s existing inventory management systems.

- Action: Ensure that all parts printed onboard are logged and tracked through the ship’s inventory management system. This includes updating part specifications and stock levels in real-time.

- Benefit: Maintains accurate records of inventory, aids in the efficient management of resources, and ensures that the availability of critical parts is always known and managed.

19. Evaluate Environmental Impact

- Objective: Assess and minimize the environmental impact of onboard 3D printing operations.

- Action: Conduct environmental assessments to understand the impact of 3D printing materials and processes on the marine environment. Implement changes to reduce waste and emissions where possible.

- Benefit: Demonstrates environmental responsibility, reduces potential harm to marine ecosystems, and aligns with broader sustainability goals of the maritime industry.

20. Scale Up Based on ROI and Feedback

- Objective: Evaluate the effectiveness and return on investment (ROI) of the 3D printing setup and decide on scaling up the operation.

- Action: After an initial trial period, review the cost savings, reduced downtime, and other benefits obtained from using 3D printing. Based on this analysis and crew feedback, consider expanding the use of 3D printing technology to other ships in the fleet.

- Benefit: Ensures that the expansion of 3D printing capabilities is justified by tangible benefits, leading to more informed decisions about investments and technology scaling.

Adopting 3D printing technology onboard ships represents a significant step forward in maritime operations, offering unparalleled efficiency and self-sufficiency in managing repairs and maintenance. By following these 20 strategic tips, you can ensure a smooth and effective integration of 3D printing into your ship’s daily operations. As the maritime industry continues to advance, staying ahead of technology trends like 3D printing will not only optimize operational capabilities but also position your fleet as a leader in innovative maritime solutions. Embrace these changes with confidence, knowing you have the knowledge and strategies to excel in the new era of maritime technology.

Do you have a Maritime Product or Service that may be of interest to Shipowners? Tell us about it here!

Do you have feedback or insights? Please reach out to editor @ shipuniverse.com