Setting Sail with 3D Printers: The New Horizon for Commercial Shipping

In today’s rapidly-evolving technological landscape, 3D printing—also known as additive manufacturing—stands out as a revolutionary tool with broad applications. For the maritime industry, integrating 3D printers on commercial ships promises not only to streamline operations but also to bring a paradigm shift in how vessels operate and maintain their daily activities. Here, we delve into the potential benefits of hosting a 3D printer onboard as well as current models that could be used in commercial vessels.

* Please send feedback/suggestions to editor @ shipuniverse.com

1. Reducing Dependency on Spare Parts Inventory: Traditionally, ships have had to stockpile a plethora of spare parts, anticipating potential breakdowns during long voyages. With a 3D printer, ships can produce parts on-demand, significantly reducing the need for extensive inventories. This not only saves space but also cuts down on the weight, leading to potential fuel savings.

2. Expedited Repairs and Reduced Downtime: In situations where a specific part breaks down, waiting for a replacement can be both time-consuming and costly, especially if the ship is in a remote location. With the capability to print the required part on-site, repair times are drastically reduced, ensuring minimal downtime and maintaining operational efficiency.

3. Cost-Efficiencies: While the initial investment in a quality 3D printer might seem significant, the long-term savings from reduced spare part shipments, lower inventory costs, and decreased downtimes can quickly offset this. Additionally, with the flexibility to produce parts as needed, ships can also avoid the markups associated with purchasing through intermediaries.

4. Customization and Innovation: 3D printing doesn’t just replicate existing parts; it allows for on-the-fly customization. Crew members can tweak designs to better suit specific needs or conditions. This adaptability fosters innovation, allowing ships to continuously improve and optimize their equipment and operations.

5. Enhanced Sustainability: 3D printing can contribute to greener operations in several ways. First, by reducing the need to ship spare parts across the world, it cuts down on transportation-related emissions. Additionally, printing parts on-demand means fewer resources are wasted on unnecessary components. Ships can also explore using sustainable materials for printing, further reducing their environmental footprint.

6. Preparedness for Emergencies: In critical situations where specific tools or components are urgently needed, having a 3D printer onboard can be a game-changer. Whether it’s a tool for an unexpected repair or a component crucial for the ship’s safety, the ability to produce it immediately can make a significant difference.

- Stratasys:

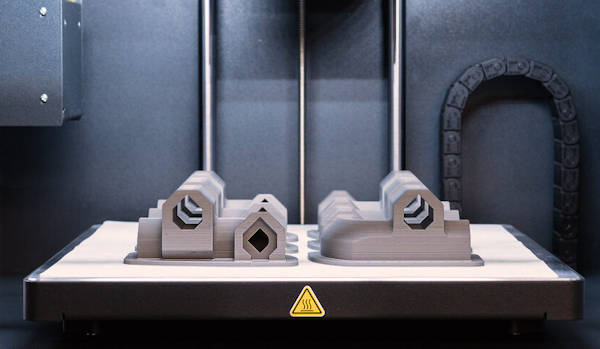

- Fortus 450mc: Known for its reliability and capability to print with a variety of materials, including high-performance thermoplastics.

- F900: Offers a large build size, making it suitable for creating larger parts or multiple components in one go.

- 3D Systems:

- ProX DMP Series: These are metal 3D printers suitable for producing metal parts that could be used in engine repairs or other critical ship systems.

- Figure 4: Offers high-speed production with precision, suitable for producing smaller components quickly.

- Ultimaker:

- Ultimaker S5: Recognized for its ease of use, versatility in materials, and high-quality prints, this could be a good option for ships that need a more general-purpose printer.

- Markforged:

- Metal X: As the name suggests, it’s a metal 3D printer which can be used to produce strong and durable parts.

- X7: Known for its ability to produce carbon fiber-reinforced parts, making them both lightweight and strong.

Discover your Ideal 3d Printing Solution Today

Do you have a Maritime Product or Service that may be of interest to Shipowners? Tell us about it here!

Do you have feedback or insights? Please reach out to editor @ shipuniverse.com