Sustainable Practices in Fluid Management

As the maritime industry increasingly focuses on sustainability, ship owners are finding that environmentally friendly practices not only help protect the planet but also offer substantial financial benefits. One critical area where sustainable practices can make a significant impact is fluid management. Today we explore how adopting sustainable fluid management practices on bulk carriers can lead to reduced operational costs, extended equipment lifespan, improved energy efficiency, regulatory compliance, and enhanced marketability.

There are several financial benefits for ship owners in adopting sustainable practices in fluid management for bulk carriers:

- Reduced Operational Costs: Sustainable practices often involve optimizing the use of fluids, leading to reduced consumption and waste. This optimization can lower costs for purchasing, storing, and disposing of these fluids.

- Extended Equipment Lifespan: Proper and sustainable fluid management can reduce wear and tear on equipment. For example, using high-quality lubricants and coolants can minimize engine and machinery breakdowns, leading to fewer repairs and replacements, thereby extending the lifespan of the equipment.

- Energy Efficiency: Sustainable practices, such as using advanced lubricants that reduce friction, can improve the overall energy efficiency of the vessel. This efficiency translates to lower fuel consumption, resulting in significant cost savings.

- Regulatory Compliance and Avoidance of Fines: Adopting sustainable practices ensures compliance with international regulations, such as MARPOL (Marine Pollution) and Ballast Water Management Convention. Non-compliance can result in hefty fines and penalties, so staying compliant avoids these financial risks.

- Insurance Premium Reductions: Some insurance companies offer reduced premiums for vessels that demonstrate sustainable practices and compliance with environmental regulations. This reduction is because sustainable practices can lower the risk of accidents and environmental incidents.

- Enhanced Marketability and Charter Rates: Vessels that follow sustainable practices may be more attractive to charterers and clients who prioritize environmental responsibility. This preference can lead to better charter rates and more business opportunities.

- Tax Incentives and Grants: In some regions, governments offer tax incentives, rebates, or grants for adopting green technologies and sustainable practices. Ship owners can take advantage of these financial incentives to offset the costs of implementing sustainable fluid management systems.

- Improved Crew Efficiency and Safety: Sustainable practices often involve better training and safer handling of fluids, leading to improved efficiency and safety for the crew. A safer working environment can reduce accidents and associated costs, such as medical expenses and compensation claims.

- Reduced Environmental Cleanup Costs: Preventing spills and leaks through sustainable fluid management reduces the risk of costly environmental cleanups and associated legal liabilities.

- Reputation and Brand Value: Companies known for their commitment to sustainability can enhance their reputation and brand value. A positive reputation can attract more business, partnerships, and investment opportunities.

Example Scenarios and Calculations

Scenario 1: Fuel Savings Through Improved Lubrication

- A bulk carrier using advanced, sustainable lubricants can reduce engine friction, improving fuel efficiency by 2%.

- If the vessel consumes 30,000 tons of fuel annually, a 2% reduction equals 600 tons saved.

- At a fuel price of $500 per ton, this translates to $300,000 in annual savings.

Scenario 2: Avoiding Fines Through Compliance

- A ship owner who invests $50,000 in a compliant ballast water treatment system avoids potential fines of $200,000 for non-compliance.

- Additionally, the compliant system ensures continued operations without interruptions, preventing potential revenue loss.

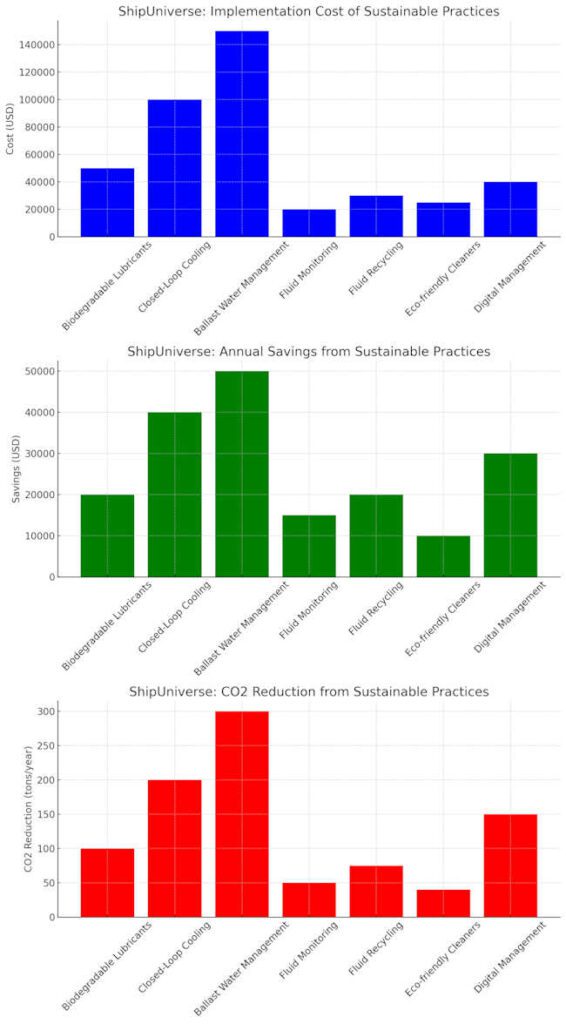

Key Sustainable Fluid Management Practices for Cargo Ships

1. Use of Biodegradable Lubricants and Hydraulic Oils

Biodegradable lubricants and hydraulic oils are designed to break down naturally in the environment, reducing pollution risks. These products provide effective lubrication and hydraulic power while being less harmful to marine ecosystems in case of leaks or spills.

Implementation:

- Switch to biodegradable lubricants and hydraulic oils for all machinery and hydraulic systems on board.

- Regularly monitor and maintain these fluids to ensure optimal performance and environmental compliance.

2. Closed-Loop Cooling Systems

Closed-loop cooling systems recirculate coolant, minimizing the need for fresh coolant and reducing the risk of contaminant discharge into the marine environment. These systems are more efficient and environmentally friendly.

Implementation:

- Retrofit existing cooling systems to closed-loop designs where feasible.

- Regularly check for leaks and maintain the integrity of the closed-loop system to prevent coolant loss and contamination.

3. Efficient Ballast Water Management Systems

Advanced ballast water management systems treat ballast water to remove or neutralize harmful organisms and pollutants. These systems ensure compliance with international regulations and protect marine biodiversity.

Implementation:

- Install state-of-the-art ballast water treatment systems that use filtration and UV radiation or chemical treatment.

- Regularly service and maintain the ballast water treatment systems to ensure they operate effectively and comply with regulatory standards.

4. Regular Fluid Monitoring and Analysis

Regular monitoring and analysis of all onboard fluids can help detect contaminants and degradation early, allowing for timely interventions. This practice ensures that fluids are always in optimal condition, reducing waste and improving equipment performance.

Implementation:

- Establish a schedule for regular fluid sampling and analysis for all critical systems, including engines, hydraulics, and cooling.

- Use on-board fluid analysis kits or partner with specialized laboratories for detailed analysis and reporting.

5. Reuse and Recycling of Fluids

Implementing systems for the reuse and recycling of fluids can significantly reduce the consumption of new fluids and the generation of waste. Technologies such as centrifugation, filtration, and dehydration can purify used fluids for reuse.

Implementation:

- Invest in equipment that can clean and recycle used lubricants, hydraulic oils, and coolants.

- Train the crew on proper collection, handling, and recycling procedures to maximize fluid reuse.

6. Environmentally Friendly Cleaning Agents

Switching to environmentally friendly cleaning agents for machinery and tanks reduces the discharge of harmful chemicals into the sea. These cleaning agents are effective in removing residues without compromising environmental safety.

Implementation:

- Replace traditional cleaning agents with biodegradable and non-toxic alternatives.

- Ensure all cleaning activities are conducted in designated areas with appropriate containment to prevent accidental discharge.

7. Digital Fluid Management Systems

Adopting digital fluid management systems enables precise tracking and control of fluid levels and quality. These systems provide real-time data, helping to optimize fluid use and maintenance schedules.

Implementation:

- Install sensors and digital monitoring equipment for all critical fluid systems.

- Utilize software solutions to track fluid consumption, schedule maintenance, and predict replacement needs.

8. Crew Training and Awareness

Educating the crew about sustainable fluid management practices is crucial for successful implementation. Training programs should cover the importance of sustainability, proper handling and disposal of fluids, and the use of new technologies.

Implementation:

- Develop and conduct regular training sessions on sustainable fluid management practices.

- Create easy-to-follow manuals and guidelines for the crew to reference during operations.

Implementing these sustainable practices in fluid management can help bulk carrier operators not only comply with environmental regulations but also realize significant financial benefits. By adopting biodegradable products, closed-loop systems, efficient treatment technologies, regular monitoring, recycling, eco-friendly cleaning agents, digital management tools, and comprehensive crew training, ship owners can enhance operational efficiency, reduce costs, and contribute to the protection of marine environments.

Do you have a Maritime Product or Service that may be of interest to Shipowners? Tell us about it here!

Do you have feedback or insights? Please reach out to editor @ shipuniverse.com